Read Time : 5 Minutes

What is a Heat Recovery System

Heat recovery and ventilation system information

Introduction to Heat Recovery Systems

We produce energy and heat everywhere we go and we do it practically all the time – in our houses, in the office, at school, during our leisure time and in industry. When the boiler comes on or the heating gurgles into life, when factories burst into action to produce the products we use daily, and when we switch on the oven or do the washing, across the board, a large amount of heat is wasted, disappearing through vents or through inefficient industrial flues into the atmosphere. Heat recovery systems make sure that the heat we produce on a daily basis is not wasted. This can include the warmth created by an office environment, the heat from an oven in a restaurant kitchen, or the ongoing emissions of factories and processing plants that would otherwise go to waste. Not only that, heat recovery can work to draw warmth from places you may not even have thought of like the air outside or the ground in your garden. It allows us to be more efficient and can help reduce the amount we pay for our energy bills.

How do Heat Recovery Systems Work?

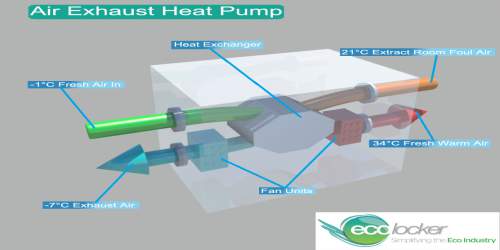

When something hot passes next to something cold, the heat travels towards the region of lower temperature in what is called a heat exchange. Being green is not just about making use of renewable technologies, it’s also concerned with making the most of what we produce. It’s about getting that warmth we create almost constantly to work just a little harder by recycling it back into our buildings. Find out more about how heat recovery systems work.

COMPARE PRICES FROM LOCAL INSTALLERS

Compare prices from local companies fast & free

Enter your postcode to compare quotes from leading professionals. We promise to keep your information Safe & Secure. Privacy Policy

Types of Heat Recovery System

Heat recovery comes in many shapes and sizes from plate exchange systems to boiler economisers and heat pumps. They all do the same job, however, making sure that the heat in our homes, offices or factories isn’t lost. For heat recovery and ventilation systems this usually involves some type of heat exchanger that sits in the loft or on the roof, drawing the cold air from outside and warming it with the help of the stale air that is being expelled from the inside. Discover the different types of heat recovery system.

Domestic Heat Recovery and Ventilation Systems

Most older buildings are usually ventilated in a very simple way – by opening windows and doors, something that we’ve been doing for hundreds of years. Modern buildings are now much more airtight and increasingly use heat recovery and ventilation systems that keep the air fresh and warm. For domestic premises, the heat recovery unit normally goes in the attic and a network of vents feed into each room and they can help save a significant amount of money on energy bills. Find out how domestic HRVSs can be a good idea for your home.

Heat Recovery for Large Scale Boilers

Recovering part of the heat lost by large scale boilers can produce huge financial savings for industry, as well as lowering their overall carbon footprint. The boilers that are used in these processes can be up to 40 years old and built at a time when efficiency wasn’t so high up on the agenda. Attaching flue economisers to boiler outlets enables the escaping heat to be caught and fed back into the system, raising the heat of water and reducing what is known as ‘thermal shock’. Explore the world of heat recovery in large scale boilers.

Large Scale Heat Recovery and Ventilation

One of the main areas where heat recovery and ventilation systems makes a big difference is in industry. From power stations to large scale factories, the battle is on to reduce our energy usage and make the world of mass production more carbon neutral and sustainable. Whether it’s the huge steam producing boilers in our factories or the massive heat generated by industrial ovens, the principal of heat exchange is the same. It’s just the size that varies. Enter the world of large scale heat recovery.

What are the Potential Uses of a Heat Recovery System?

In both commercial and domestic environments there a host of uses for this kind of technology including the heating and ventilation of spaces, water heating, pre-heating air and water to increase the efficiency of boilers and reduce costs, and its use in industrial processes such as large scale drying. Uncover the true potential of heat recovery.

Benefits of Heat Recovery

Making the most of heat recovery systems in your home or business can lead to substantial savings on your fuel bills. Recycling that stale air and drawing the useful heat from it to help keep you warm in the winter and cooler in the summer can make all the difference to your health whilst reducing your carbon footprint. It also has major benefits in the world of industry where heat loss is often a major concern. Find out more about the benefits of heat recovery.

Integration of Heat Recovery into Existing Systems

The wide ranging benefits of any heat recovery technologies can help get the most out your existing systems. If you have had a micro-generation system such as solar panels or a biomass boiler installed then it makes sense to integrate heat recovery to add power to your sustainability and improve your green credentials. It also helps you save more money at the same time. Discover how you can integrate heat recovery into your home.

Heat Recovery System Efficiencies

Apart from heat pumps, heat recovery systems are generally not considered as renewable technologies but they do allow us to make the most of the energy that we produce. Efficiencies vary across the different types of heat recovery and will often depend on a number of other factors such as how airtight your house is or the age and make of a particular boiler. Find some typical heat recovery efficiencies here.

Is Installing a Heat Recovery System Worth the Effort?

There’s no doubt that a lot of work has to go into making our homes and offices more energy efficient. Installing a heat recovery system can present a significant outlay but can also help reduce fuel bills and make us more sustainable. With energy prices set to rise in the near future, measures like heat recovery may well protect consumers against exorbitant fuel bills by helping them to manage their energy consumption more effectively. Explore how a heat recovery system could work for you.

Heat Recovery System Cost

You can expect to pay between £2,000 and £5,000 for a domestic heat recovery and ventilation system but costs will vary according to the size of your property and the amount of retrofitting required. For industrial and commercial premises, obviously the cost can spiral into the hundreds of thousands but the energy savings that come from a good heat recovery system can offset the initial investment quite quickly. The costs of different heat recovery systems.

Heat Recovery System Potential Savings

Because they are designed to reduce your carbon footprint and help bring down those fuel bills by making the most of what you have, heat recovery systems can offer quite large potential savings for both domestic and commercial premises. Whilst many manufacturers will boast 90% efficiencies, most heat recovery systems can save you between 50 and 70% of heat lost due to wastage. Find out how much you can save with a heat recovery system.

Heat Recovery System Maintenance

Every piece of installed technology needs some kind of maintenance now and again. With heat recovery and ventilation systems it could be something as simple as replacing the air vent filters and with an industrial size boiler it could mean more extensive and intensive work on a regular basis. Maintenance of your system ensures it works to its full capacity and prevents more serious problems occurring further down the line. Decide what maintenance your heat recovery system will need.

Installers of Heat Recovery Systems

Finding the right installer for your heat recovery system can often be a daunting process. Whether it’s a flue economiser for your boiler, a heat pump to draw the warmth out of the ground outside, or a full heat recovery and ventilation system with all its vents and piping, you can search our database for the right company in your area here and get some good advice on what to look out for.

Manufacturers of Heat Recovery Systems

Heat recovery has been around for some years now and there are plenty of manufacturers both here in the UK and globally who have a pretty good track record for innovation and development. Most installers will be aligned to a specific manufacturer and it’s always a good idea to check out the people who are actually making the technology that is being installed. Find out more about heat recovery manufacturers here.

Heat Recovery Systems – Legislation and Law

Legislation and law are growing as the renewable and energy efficiency agenda moves forward. From the government’s national standard for building more sustainable homes to the existing legislation that protects consumers, it’s always a good idea to know what your rights are. Find out more about the legal side of heat recovery here.

|

|

Find a local installer

Welcome to the biggest directory of UK renewable energy companies

How do heat recovery systems work

How do heat recovery systems work