Read Time : 3 Minutes

How does microCHP technology work in homes and businesses?

Historical Application of CHP

CHP systems have been used successfully in the industrial sector since 1970 but the technology hasn’t been widely applicable for domestic use, largely due to the system's size, weight, noise and cost. In industry, CHP systems are small ‘Heat Engines’ that provide all the power for an individual building.

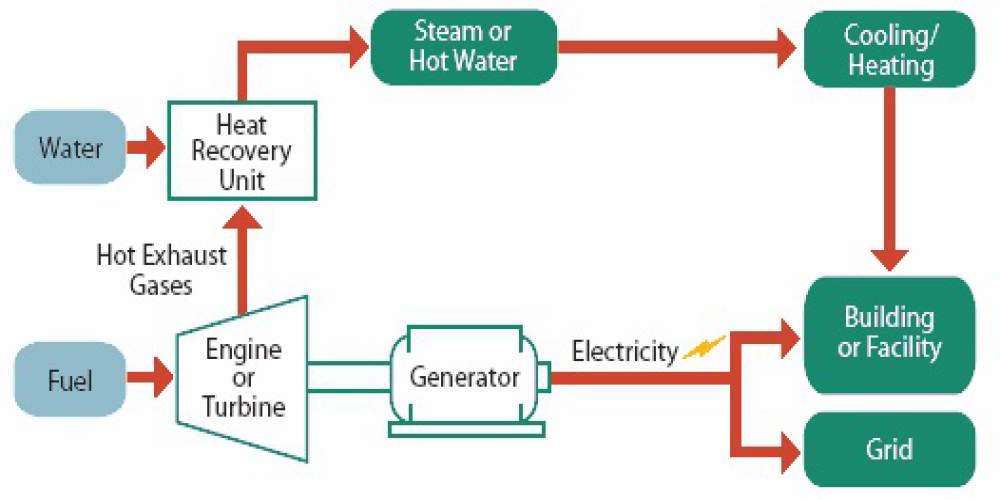

It is by harnessing the wasted heat from this process and using it for hot water, heating or cooling that the phrase 'combined heat and power' (CHP) is defined.

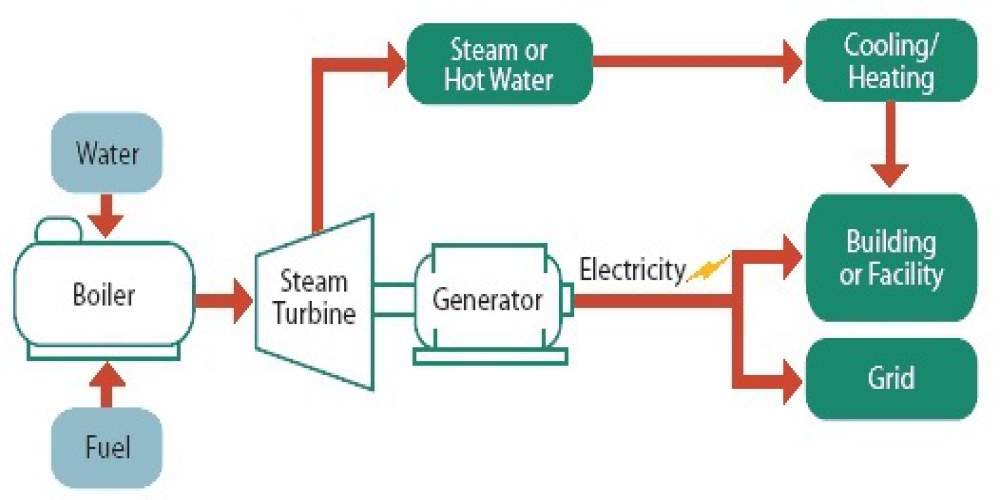

Turbine Based CHP Process Diagram

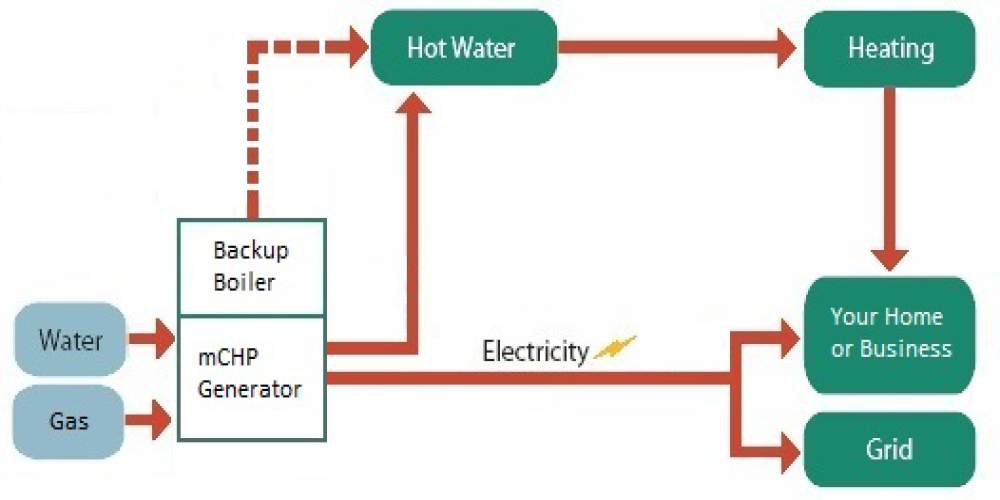

Boiler Based CHP Process Diagram

COMPARE PRICES FROM LOCAL INSTALLERS

Compare prices from local companies fast & free

Enter your postcode to compare quotes from leading professionals. We promise to keep your information Safe & Secure. Privacy Policy

Domestic and SME applications for microCHP

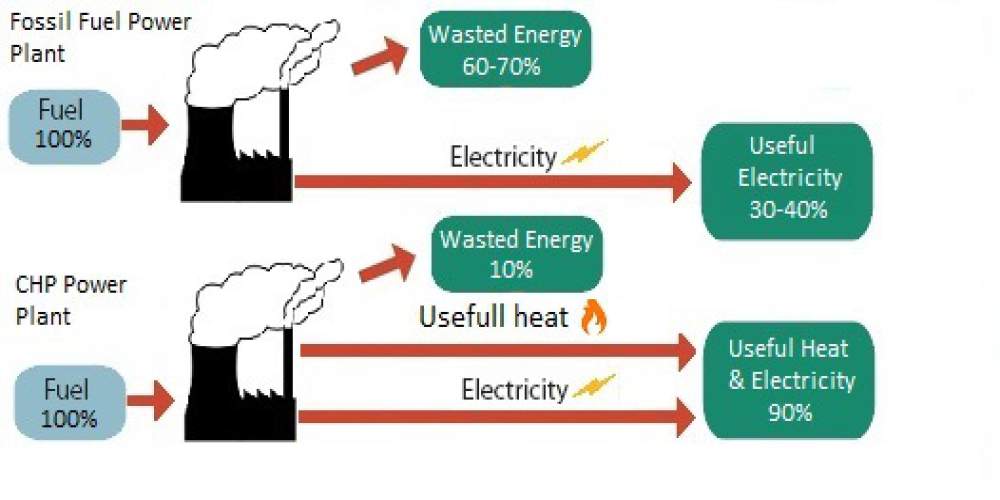

For domestic and small to medium enterprise (SME) applications, the microCHP unit in your home or business will do much the same as the larger scale CHP methods but on a much smaller scale. As previously mentioned, at an industrial scale, a vast amount of energy is wasted, both in its creation at the power plant and in its transference to your home or business (this industrial process can be as low as 30% efficient).

It is this on-site, co-generation method that greatly increases the efficiency of the energy production process and thereby lowers the combined carbon footprint and reduces your reliance on expensive 'dirty' electricity from the national grid. mCHP boilers claim efficiencies of up to 98%!

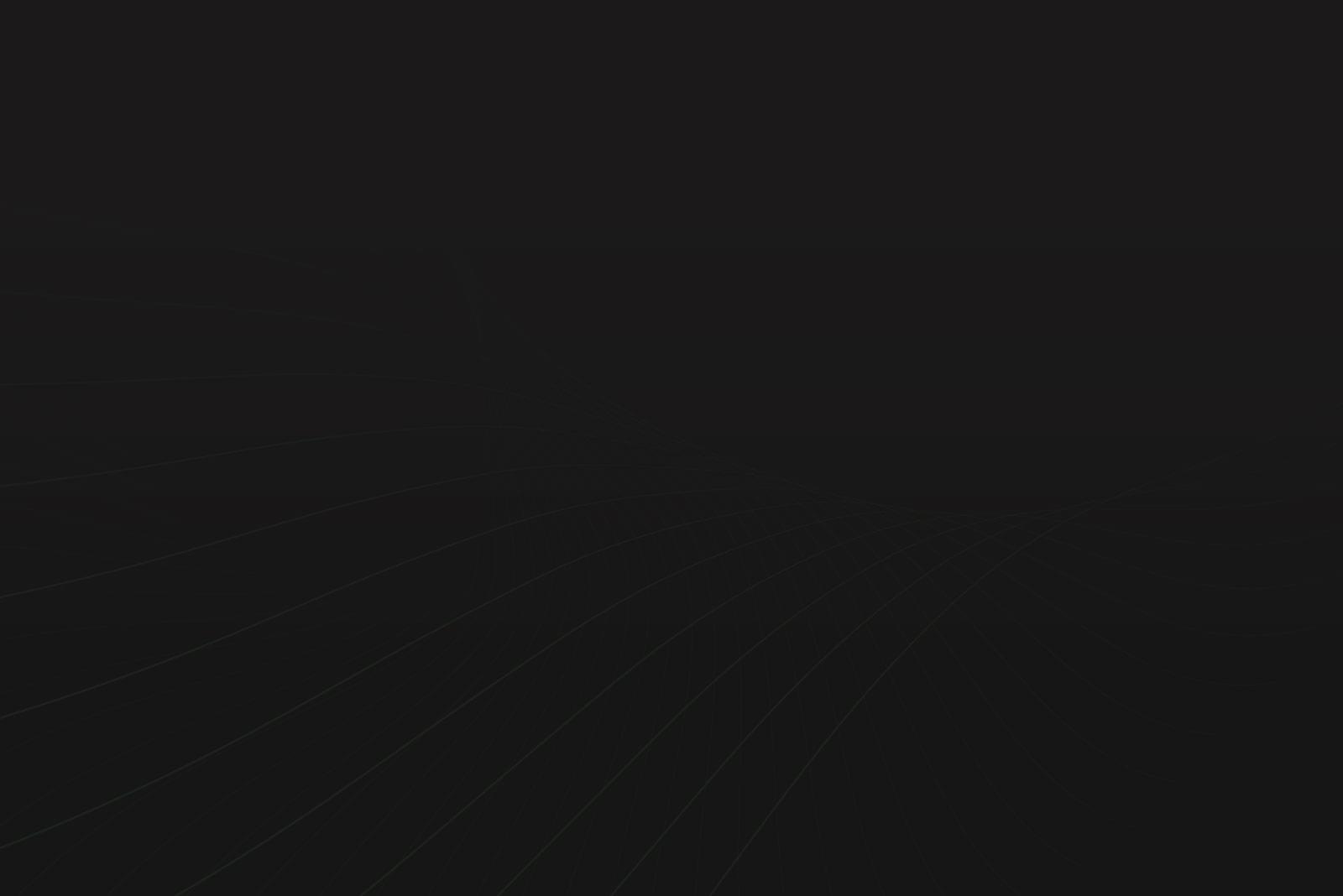

MicroCHP Process Diagram

MicroCHP for the domestic household is a relatively new technology. Up until 2006 the economic viability when looking at the available ‘domestic’ unit's payback period, rendered the micro-CHP technology unfit for domestic use, however this is all set to change in the near future, with many competitively priced units preparing to be released to the wholesale market.

As they begin to appear on the UK market, please check HERE as we will list both the units themselves and installers who will supply and fit them for you.

microCHP in industry

Large scale 'Heat Engine Systems' (power plants), are used to generate electrical power for modern life, by burning a variety of fuels and converting them into mains electricity. They are however, extremely inefficient - they are unable to convert all the energy from the fuel they burn into electricity and some of the electricity is lost upon transmission through the national grid to your home or business.

It is the wasted heat from this process that can be utilised by a microCHP system and turned into heat and hot water for your property.

Combined Heat and Power (CHP), also known as cogeneration, is a highly efficient approach to generate electricity and utilize the waste heat produced during the process for various industrial purposes. One compelling example of CHP in the industry can be found in a large-scale petrochemical plant.

Natural gas is utilized as the primary feedstock for producing various petrochemical products. Traditionally, this process involves the combustion of natural gas to generate electricity and the release of substantial amounts of waste heat into the atmosphere. However, by implementing a CHP system, the plant maximizes energy utilization and minimizes environmental impact.

The CHP system in the petrochemical plant comprises a gas turbine and a heat recovery steam generator (HRSG). The gas turbine efficiently converts natural gas into electricity, and the exhaust gases, which are still high in thermal energy, are directed into the HRSG. In the HRSG, the waste heat is used to generate high-pressure steam.

This steam is then utilized in various processes within the plant, such as heating chemical reactors, distillation columns, and providing hot water for other industrial needs. By integrating CHP, the petrochemical plant achieves an overall efficiency of up to 80% or more, which is significantly higher than conventional power generation systems.

Not only does CHP enhance the plant's energy efficiency, but it also reduces greenhouse gas emissions, helping the facility meet sustainability goals and contribute positively to the environment. The example of CHP in this petrochemical plant showcases the immense potential of cogeneration in various industries, emphasizing the importance of adopting environmentally friendly and economically viable energy solutions.

Power Plant Efficiency Diagram

In conclusion

Find a local installer

Welcome to the biggest directory of UK renewable energy companies

Types of CHP and Micro CHP Technology

Types of CHP and Micro CHP Technology

Micro Combined Heat and Power (micro-CHP) boilers are innovative and energy-efficient systems designed to provide both heat and electricity for domestic properties. These compact devices are gaining popularity as a sustainable solution to meet the energy demands of households while reducing carbon emissions and overall energy costs.

Micro-CHP boilers work on the principle of cogeneration, wherein they simultaneously produce heat for space and water heating, similar to traditional boilers, but with an added advantage of generating electricity. The key components of a micro-CHP boiler include a small-scale internal combustion engine, a generator, and a heat exchanger. These components work in harmony, using various fuels such as natural gas, propane, or biofuels, to deliver reliable and constant power and heat.

The electricity produced by micro-CHP boilers can be utilized to power household appliances and lighting, reducing dependency on the national grid and potentially leading to lower electricity bills. Any excess electricity can be fed back into the grid, earning homeowners incentives through feed-in tariffs or net metering schemes, making micro-CHP systems an attractive investment for those seeking to make their homes more environmentally friendly.

One of the significant advantages of micro-CHP boilers is their impressive efficiency compared to traditional power generation methods. By utilizing the waste heat generated during electricity production to meet domestic heating needs, these boilers can achieve overall efficiencies of up to 90%, which is significantly higher than conventional centralized power plants.

Furthermore, micro-CHP boilers contribute to a reduction in greenhouse gas emissions, as they produce fewer carbon emissions compared to conventional grid electricity and individual heating systems. By adopting these systems, homeowners can play a crucial role in combating climate change and reducing their carbon footprint.

Despite their numerous benefits, there are some challenges associated with micro-CHP boilers. The initial installation costs may be higher than traditional boilers, and proper maintenance is required to ensure optimal performance. Additionally, the availability of suitable fuels and grid connection regulations may vary in different regions, affecting the viability of these systems.

Micro-CHP boilers are a promising technology for domestic properties, providing a sustainable and cost-effective solution to generate heat and electricity simultaneously. With their potential to reduce carbon emissions, increase energy efficiency, and even earn incentives, micro-CHP boilers represent a step towards a greener and more sustainable future for households worldwide.