Read Time : 3 Minutes

Maintenance of Heat Recovery and Ventilation Systems

Maintenance of Heat Recovery and Ventilation Systems

There are a wide range of heat recovery systems available so the amount and technicalities of a maintenance regime will vary across each one. From cleaning out filters and checking ductwork to overhauling complex machinery like a ventilation unit or undertaking an economiser performance inspection, it’s always a good idea to iron out the details when you have your system installed.

- How often do filters need to be changed?

- What needs to be checked on a regular basis?

- How often should you have maintenance carried out?

- What needs to be done such as cleaning ductwork, fans and grills?

The Purpose of Heat Recovery Maintenance

Regular maintenance of any heat recovery system ensures that it is kept in tip-top condition, avoiding complications later in its life. With small jobs like changing the filters on ventilation systems, this is often something that can be done by the property owner. More complex maintenance will need to be carried out by a qualified engineer to avoid invalidating any warranty or causing other problems.

COMPARE PRICES FROM LOCAL INSTALLERS

Compare prices from local companies fast & free

Enter your postcode to compare quotes from leading professionals. We promise to keep your information Safe & Secure. Privacy Policy

Maintenance for Ventilation Systems

A good maintenance regime for a ventilation system, either domestic or commercial, would include:

- Checking for blocked filters.

- Cleaning dirty heat exchange surfaces that could reduce efficiency.

- Unblocking condensate drains that could cause a build-up of things like bacteria.

- Replacing damaged damper seals.

- Repairing seized damper actuators.

- Checking the controls are calibrated correctly.

Certain systems require more maintenance than others. For example, the simplest and cheapest heat recovery solution is a heat plate exchanger which, while it has a low efficiency, is pretty low maintenance too. A system with a run around coil requires a little more maintenance over time but is a more efficient method of heat recovery. Rotary wheels tend not to be used for most systems because of their size and they also have a high maintenance cost attached to them. Discover about the different types of heat recovery and ventilation systems here. The cost of maintenance for heat recovery and ventilation systems obviously depends on the circumstances and the size or complexity of the array. Most new installations will come with a warranty between 3 and 5 years that means any parts of the unit that breakdown in that time should be replaced for free. That doesn’t mean you should neglect maintenance on the system until the warranty works out. As with most machines, prevention is far better than a cure, and normally less costly.

Replacing Ventilation Filters

Domestic households who have a heat recovery and ventilation system installed will be able to carry out some parts of the maintenance themselves, including replacing the air filters on the vents that go into each room. Most manufacturers recommend that filters are replaced every six to twelve months. For commercial premises there may be concerns over health and safety and it might be more prudent to employ a qualified maintenance engineer to carry out the replacement of filters and other work that needs to be undertaken.

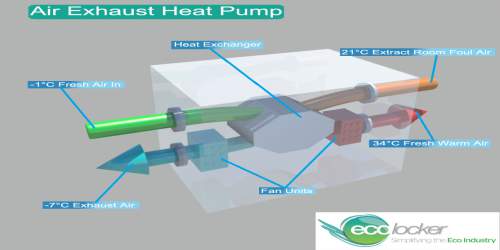

Maintenance for Heat Pumps

There are two types of heat pump that you can have installed on your property, air source and ground/water source. A good quality heat pump that has been properly installed should last anywhere up to 20 to 30 years. You will receive a list of maintenance jobs that need to be done on an annual basis when your installer puts the system in and some of these you may well be able to take care of yourself. Find out more about maintenance for heat pumps.

Maintenance for Heat Pipes

There are a wide range of heat pipes from vapour chambers to thermosyphons and they are fairly low maintenance compared to other heat transfer/recovery systems. The primary disadvantage of heat pipes is that they can only be used where the air handling is done in one system but they require little maintenance over their lifetime.

Maintenance for Flue Economisers

Flue economisers range from the systems used in commercial premises to those found in industrial boiler and heating systems so the level and frequency of maintenance will depend on a large number of factors. One of the major issues with flue economisers is ensuring that they are performing at their highest efficiency level, though they have few moving parts that require ongoing maintenance.

Finding the Right Maintenance Regime for your Heat Recovery System

Whilst your installer might well put in a full maintenance program as part of the installation which can then be added onto the cost. You may have to look for a suitable engineer to carry out maintenance and it helps to know how your system works and what things are likely to go wrong with it or need regular cleaning or replacement. Whilst your heat recovery and ventilation system may well be under warranty for the first couple of years, it pays to keep up a regular maintenance schedule at least once a year.

Find a local installer

Welcome to the biggest directory of UK renewable energy companies

How do heat recovery systems work

How do heat recovery systems work